1991

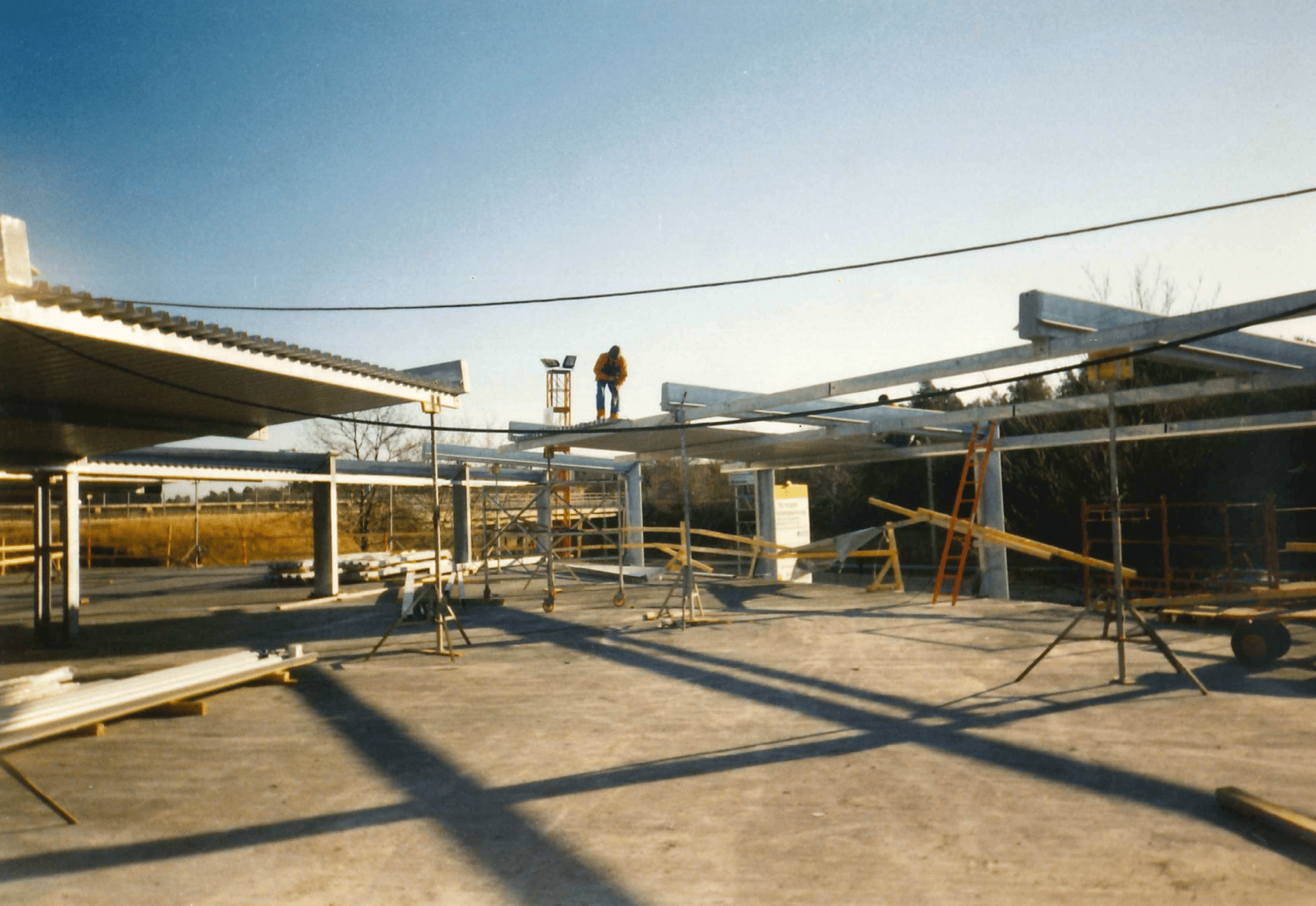

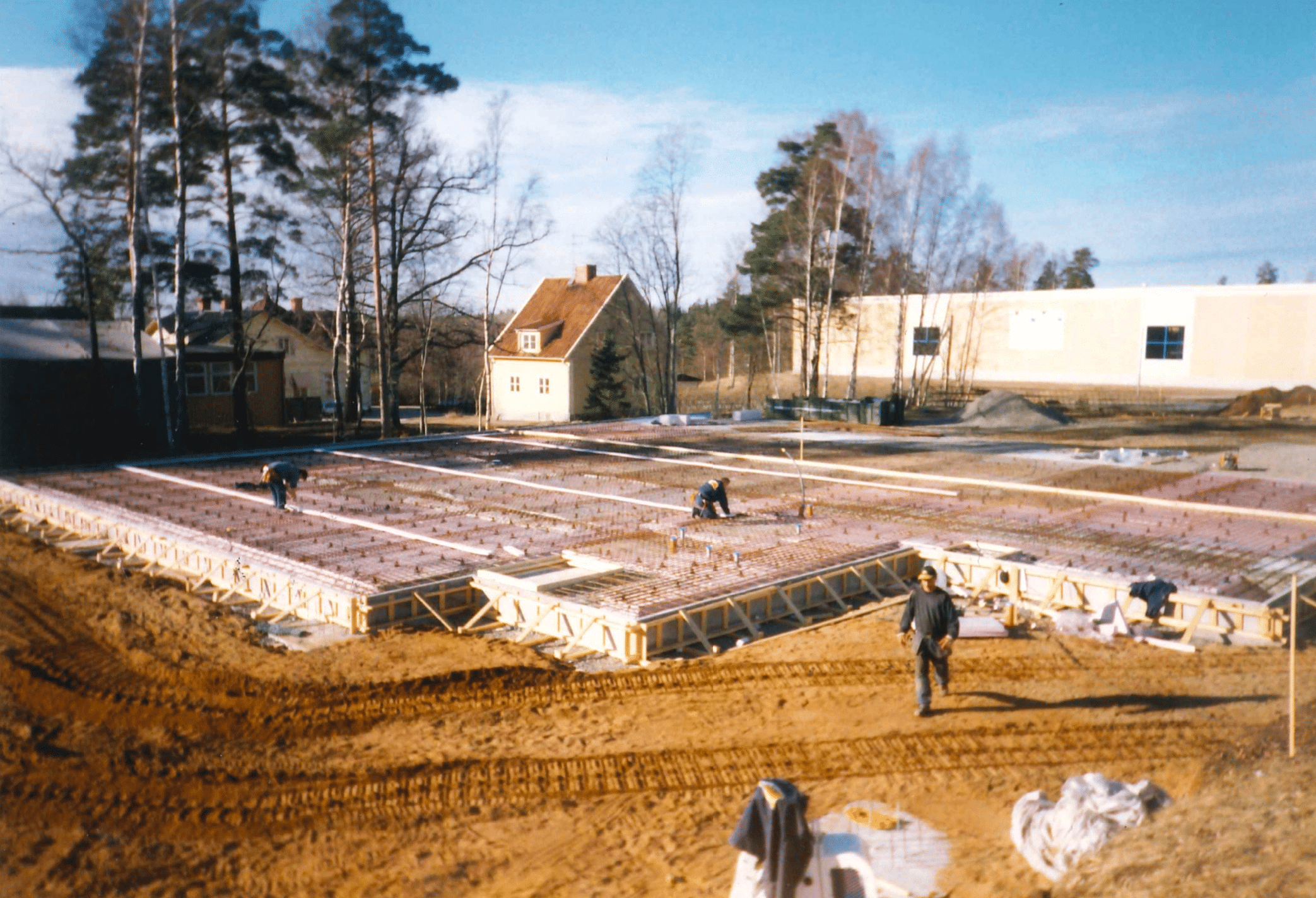

AB Smederna started up in Huddinge in spring of this year with six blacksmiths and one employee in the office. Our first job was railings at Söderberga Gård. We celebrated with a wonderful evening at Lena PH’s Krogshow 007. In the years leading up to 1994, the basis was laid for the company policy that today ensures that all employees are strongly committed to the company through training, activities involving the personnel and good working conditions. Some blacksmiths travelled around Sweden and assembled satellite stands, whereas others built the Skarpnäck and Bagarmossen underground railway stations.